Finetech Submicron bonding demonstration at WOTS

Finetech GmbH & Co. KG has almost 25 years of experience in high accuracy placement and has developed the appropriate manual and automated machines and tooling for such challenges. Even though opto-electronic and laser assembly is shown on the booth, the flexibility of their machines qualifies them for many other application than only these, especially for R&D purposes or small and medium volume production.

At WOTS Display: Fineplacer Lambda and Fineplacer Coreplus

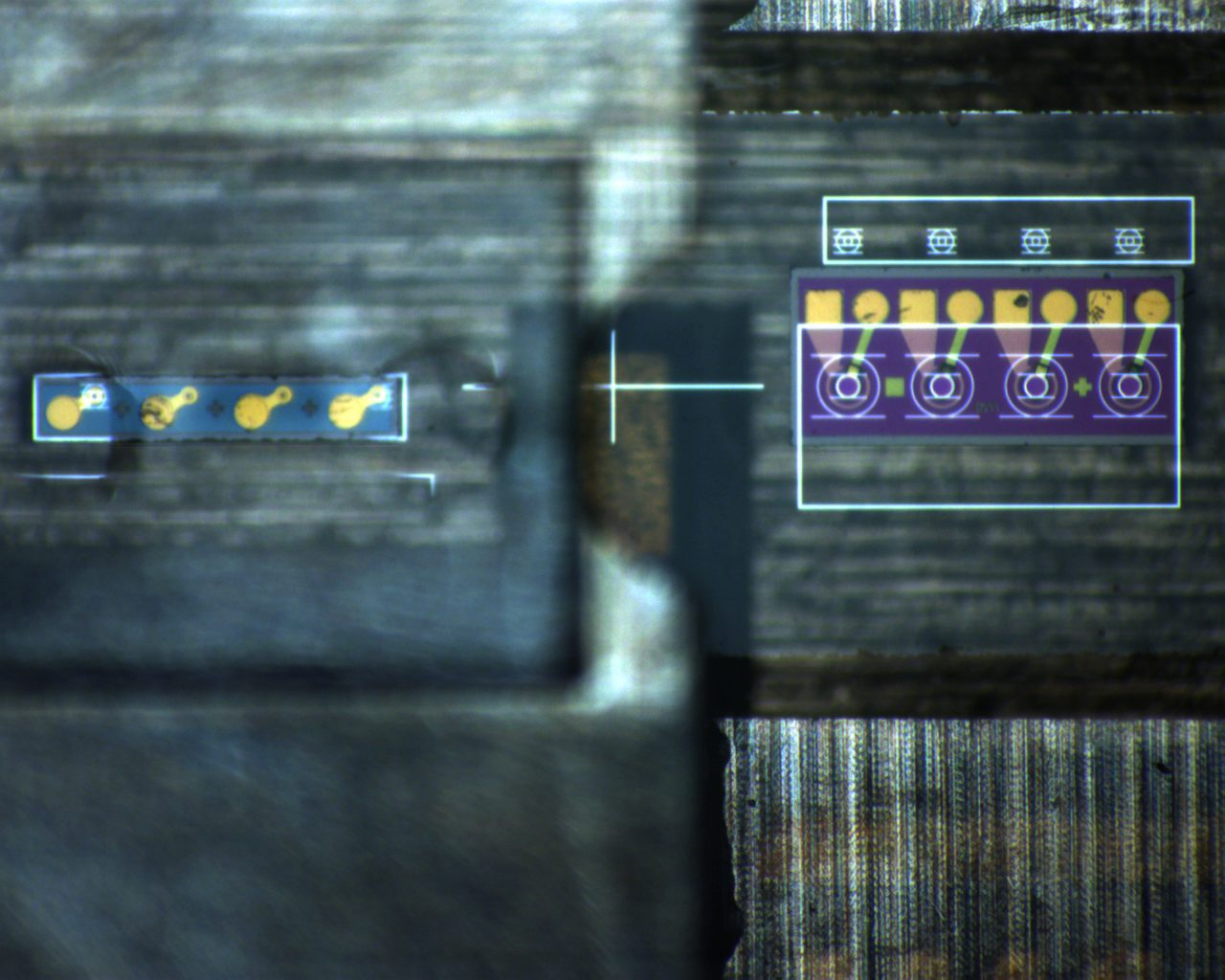

Relative VCSEL- and PD-array placement

Pairs of VCSEL and Photodiodes or arrays of them are widely used in optical data communication. Highest placement accuracy is very important for optimal coupling of the signals. Passive alignment recognizes structures of components, which are used for alignment. If all components e.g. VCSELs and PDs are placed very accurately towards each other, e.g. one big array of lenses or fibres can be aligned to them in one step instead of many of them in many steps, which saves a lot of time and therefore cost. The FINEPLACER® lambda provides 0.5µm placement accuracy for an outstanding low price and is therefore predestined for such assemblies. The passive alignment process is shown on the booth using a glass mask tool.

Laser bar soldering

High power lasers and laser bars need perfect alignment to their heat sinks to ensure max. cooling at max. power. Therefore they are also usually soldered with very thin layers of AuSn. With its very high placement accuracy and equipped with heating plate and a laser bar tool the FINEPLACER® lambda is the optimal tool for such application, which is demonstrated on the booth.