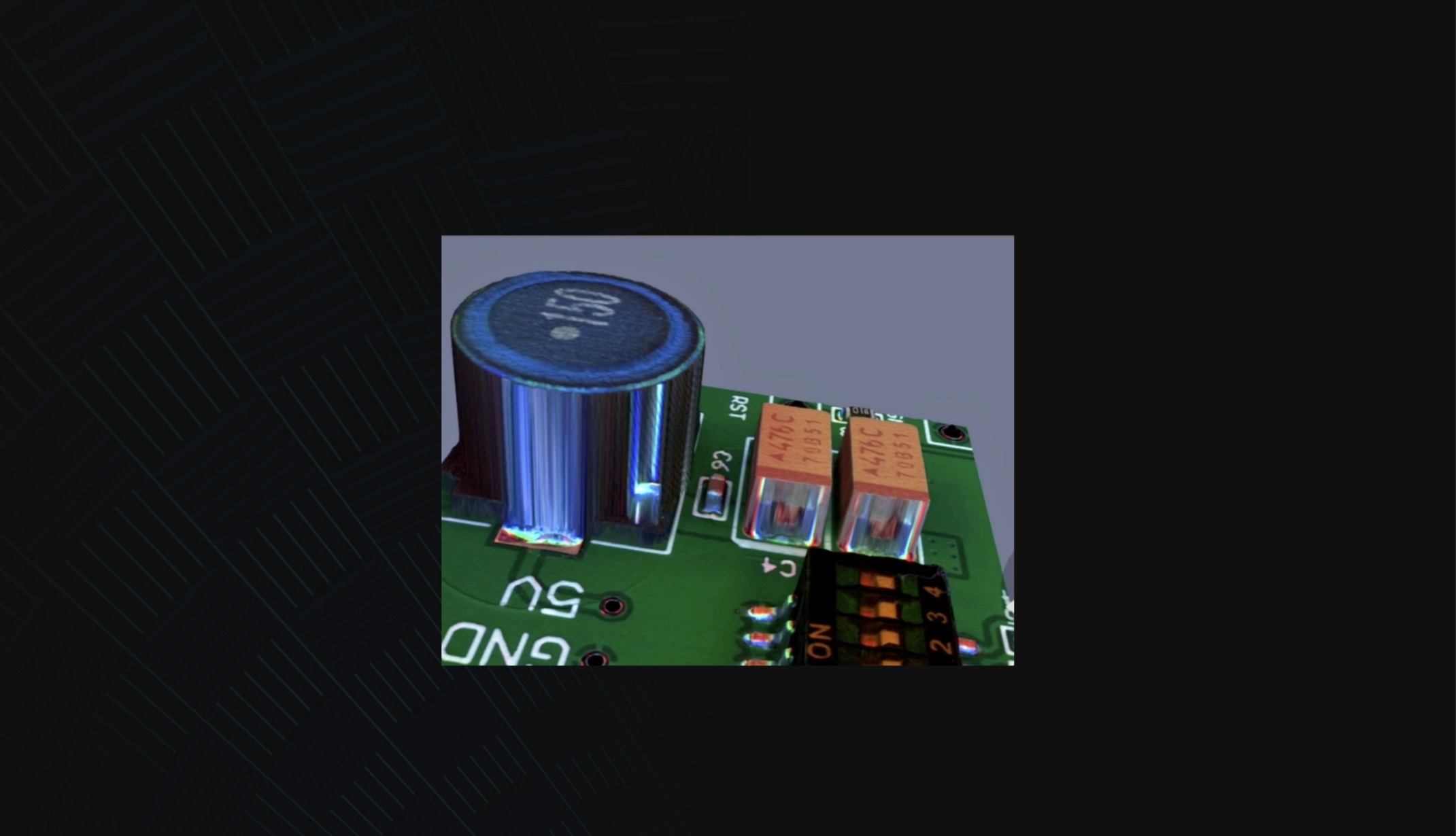

Height Section Positioning High level of information visualization

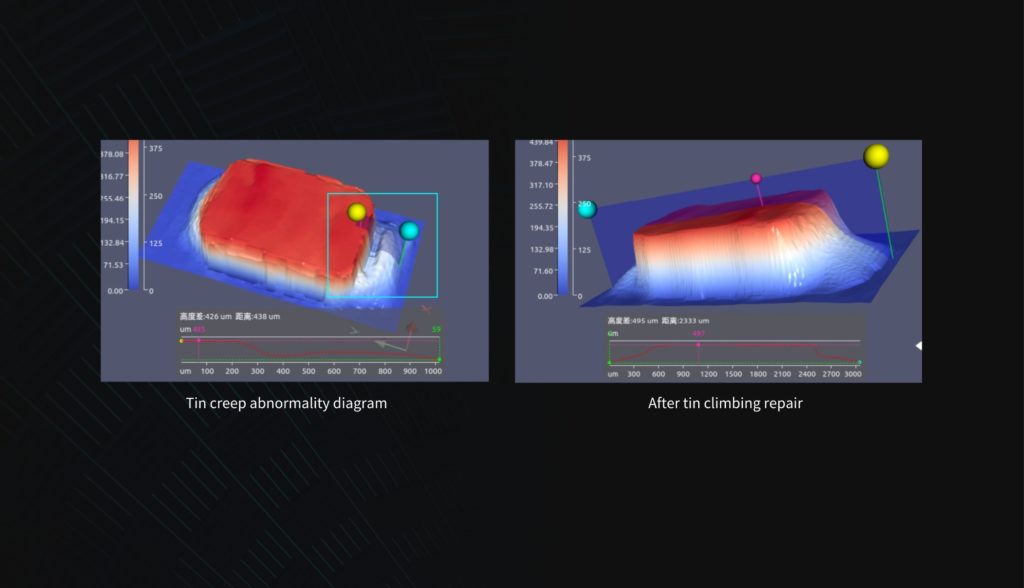

Avoid the interference from surface of component . Inspect the defects such as floating height, lifting legs, poor tin climbing, pseudo, etc.

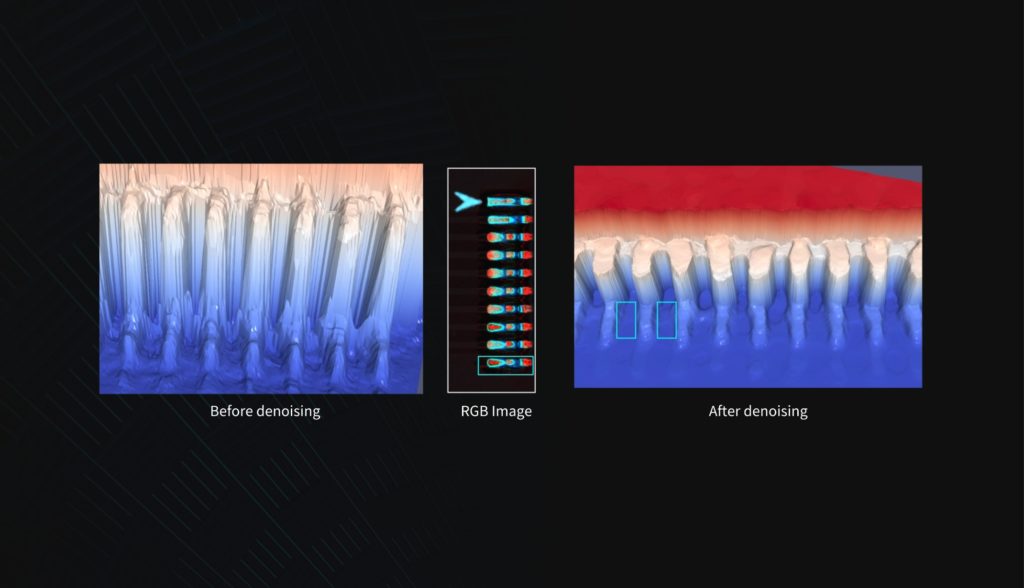

Dynamic adaptive datum ensures measurement accuracy

Non-required for manual adjustment. Self-adaptive correction to solve the mechanical error caused by the movement of the track splint and camera, bending plate compensation, thus ensuring the detection accuracy.

Multi-directional sensor Multi-view corresponding point phase consistency

Remove deep outliers, reduce noise interference on imaging, and detection false alarm rate.

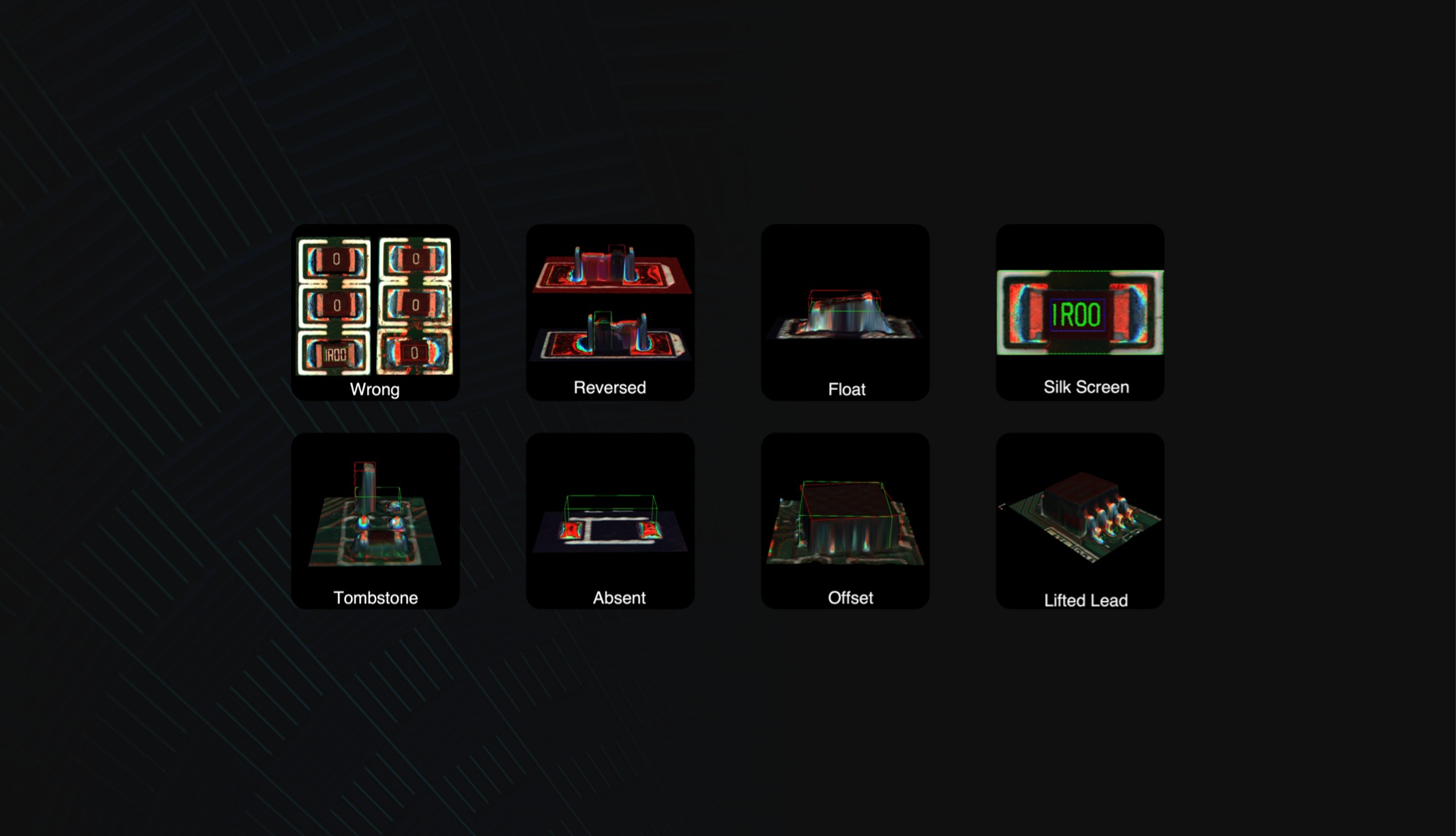

AI intelligent programming simplifies complexity and is more efficient

Search trained components automatically, calling related algorithm intelligently when drawing box in batches, calling parameter intelligently, shorten programming time and being more efficient.