SUNFLOW FS/450

Product Description

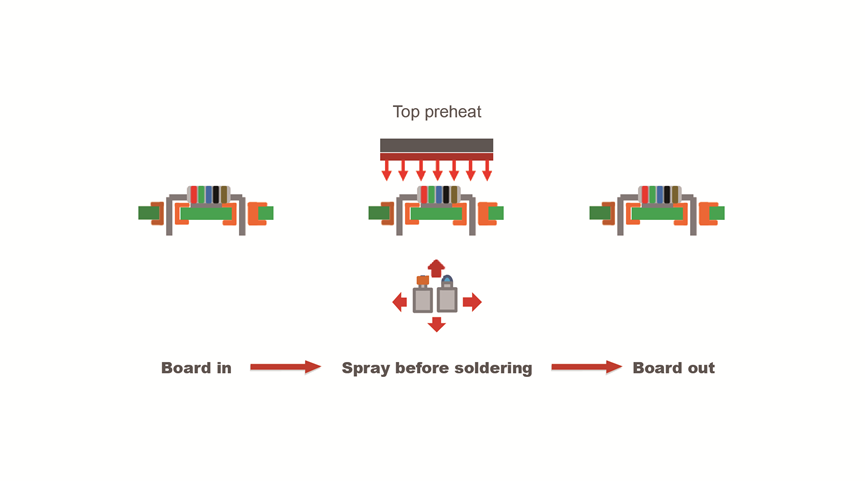

Selective wave soldering is a special form of wave soldering applied to PCB plug-in through-hole soldering. Selective wave soldering generally consists of three modules: flux spraying, preheating, and soldering. The flux nozzle moves to the command position according to the pre programmed program, and selectively spray the position to be welded. After the PCB is preheated by the upper and lower preheating modules, the welding module performs welding according to the programming path.

Application Range

Selective wave soldering is mainly used in high-end electronic products such as military aerospace, automotive electronics, railway products, switch power supplies, etc. It can meet the through-hole soldering requirements of multi-layer PCBs with high soldering requirements and complex processes.

Features

- Equip with spraying, preheating and welding units which can complete the whole welding process in a small machine

- Rotary track design which allows loading and unloading PCB on the same side of the machine

- Cover small area, shorter than the standard SUNFLOW machine

- Real time monitoring and recording of welding process

Soldering Process

- Send a PCB to the specified location

- PCB selective spraying, preheating and soldering are according to the setup program

- PCB is transported out

Basic Machine Module

- Flux Module

- Preheat Module

- Soldering Module

- Conveyor System

Working Process

After PCB is moved to flux area, the spray head is targeted to the programed position and the flux is applied only to the solder joint to be made. After preheating, the electromagnetic pump moves to the target area and solder joint is made.

Fast and Comfortable Programming

- A variety of programming options are available

- Different parameter for every soldering point

- Offline programing

- Process data record

Smooth Conveying System

Conveyor System combines chain and roller transports. Chain transport system is chosen in flux and preheating module. The soldering module use the roller transport which performs good in location board and repeatability.

High Precision Spray System

The standard machine uses a precision drop nozzle with diameter of 130μm, which can evenly spray the flux to the required soldering area. The minimum spray area is 3mm, saving at least 90% flux compared to conventional spray.

Perfect Preheating System

Combine stop heater and bottom heater and it still performs perfectly even for the lead-free soldering or multi-layer boards. Top convection heater has been proved by Sun East Reflow machine for many years and it can offer an even temperature distribution over the complete board. Bottom IR emitter heater provides optional heating area according the custom board. At the same time, another top heater covers the soldering module and it can maintain the board temperature in all the cycle time.

Stable and High Quality Soldering System

- Electromagnetic solder pump

- Stable wave height

- Quick-change solder nozzles

- Special solder nozzle

- Low maintains required

- Welding process can be recorded

Common Options

1. Automatic tinning

- Support 2mm diameter tin wire

- Support 1kg to 4kg tin wire coil installation

- Tin addition frequency and time can be set to meet the requirements of liquid level height

2. Automatic cleaning

- Powder cleaning method

- Customize the cleaning location

- Supports setting of cleaning frequency and cleaning time

- Solve the nozzle oxidation problem

3. Fiducial identification and positioning function

- High definition camera configuration

- Can set multiple image recognition modes

- The recognition function can be turned on or off separately

- Can turn on or off the recognition function separately

Or fill in the form below, to request more information.