Maker-Ray is an innovative manufacturer of intelligent optical inspection solutions. The company focuses on the research, development, and sales of advanced AOI systems that support the entire PCBA production chain, including THT, SMT, and coating processes.

As a pioneer in applying artificial intelligence (AI) to automatic optical inspection, Maker-Ray has drastically reduced programming times and significantly improved detection accuracy. With cutting-edge technology and more than 20 service centers worldwide, Maker-Ray delivers reliable solutions that are widely used in industries such as automotive electronics, consumer electronics, power supplies, and industrial applications.

Inline 3D AOI AIS431B-HW

The Maker-Ray AIS431B-HW is a high-performance inline 3D Automatic Optical Inspection (AOI) system designed for SMD inspection, combining ultra-high imaging accuracy with advanced AI-powered analysis. Equipped with a 21MP high-speed industrial area camera and structured RGBW projection lighting, it delivers ultra-realistic 3D images with resolutions of 10–13 μm and achieves inspection speeds up to 0.47 sec/FOV.

Supporting PCB sizes from 50 × 50 mm to 510 × 460 mm (expandable up to 710 × 460 mm in large-board mode), the AIS431B-HW handles component heights of 35 mm (top) and 80 mm (bottom), with optional optical adjustment for components up to 40 mm.

Key Features and Capabilities

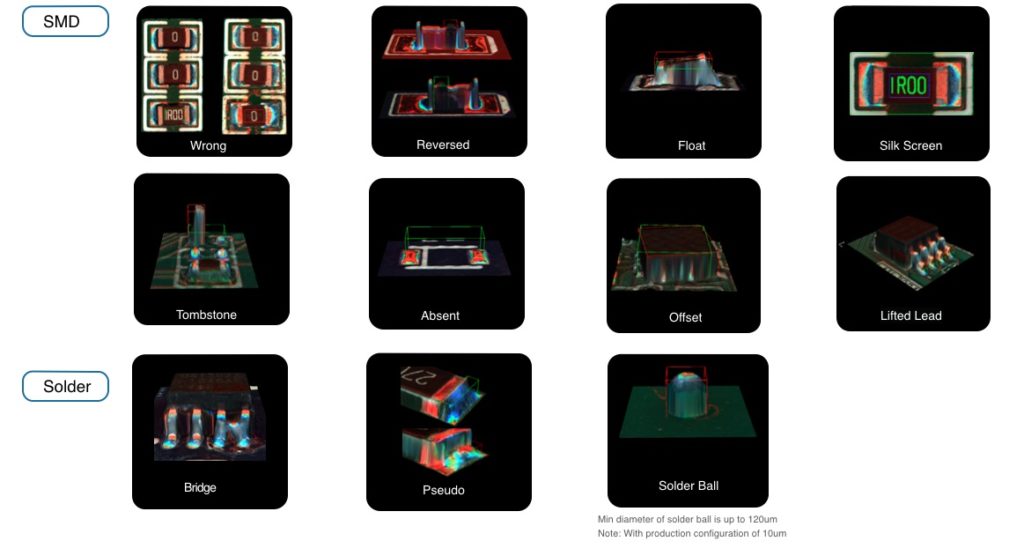

- Comprehensive defect detection: missing, wrong, polarity reversed, offset, lifted leads, damage, contamination, solder bridges, pseudo solder, voids, excessive/insufficient solder.

- Advanced AI algorithms: AI skew, AI solder insufficiency, AI misalignment, missing detection, with strong performance in multi-scene inspection (multi-panel, mixed boards, auto program switching).

- Flexible programming: CAD file import, quick programming tools, component library integration, inline “on-the-fly” fine-tuning.

- Traceability & data analytics: 1D/2D barcode & QR code reading, OCR, SPC statistical analysis, MES integration via file, TCP, HTTP, and webservice protocols.

- Additional options: 3D buy-off station, 3D offline programming PC, UPS power protection, storage upgrade (up to 10 TB).

Hardware & System Specifications

- Imaging: 21MP camera + projector, RGBW light source.

- Resolution / FOV: 10 μm (51 × 40 mm) / 13 μm (66 × 53 mm).

- Repeatability: 1 μm (with calibration block).

- Height accuracy: <1.5% @ 6σ.

- GRR: <10%.

- PCB support: thickness 0.5–6 mm, max. weight ≤ 3 kg, edge clearance 3 mm.

- Motion system: high-precision screw + servo motor, manual/auto width adjustment.

- Control system: Intel i7 CPU, RTX3060 12G GPU, 128 GB DDR4 RAM, SSD + HDD (up to 10 TB).

- Software: Ubuntu 22.04 LTS (64-bit).

- Interface: SMEMA, HTTP, webservice.

- Display: 23.8” FHD monitor.

Or fill in the form below, to request more information.