LPKF ProtoLaser H4

Best from both worlds on the table: fast and straight drilling without taper also on thick substrates and fastest surface processing with minor to none surface damage.

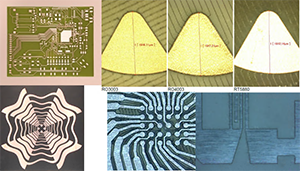

Main Applications – IR Laser

Precise structuring / ablation /laser etching of conductive metal layers on:

- Standard FR4, single, double-sided, 5-35um Cu

- Some RF materials, PTFE or ceramic filled, double-sided, processed only on a one side

- Dupont Pyralux AC, Al on PET

- ProMask ablation

- Line / Space: 100 µm / 50 µm

Mechanical Drilling & Routing

- HF spindle with 60.000 rpm

- Pneumatic collet release

- 1/8” (3,175 mm) collet

- Standard 38mm drill bits and routers

- Magazine for 6 tools

- Automatic tool exchange with depth adjustment

- Seamless workflow on one system (i.e marking drills with laser)

Benefits:

- Drilling & routing thicker materials i.e. multilayers

- Straight, smooth holes – THP

New CircuitPro RP

- UI based on known CircuitPro for ProtoLasers 3.5

- Newly designed mechanical tool libraries added

- Processes for mechanical drilling and routing added from CircuitPro for ProtoMat

- one system, one software

- Workflow distinguish between laser and mechanical drilling, cutting