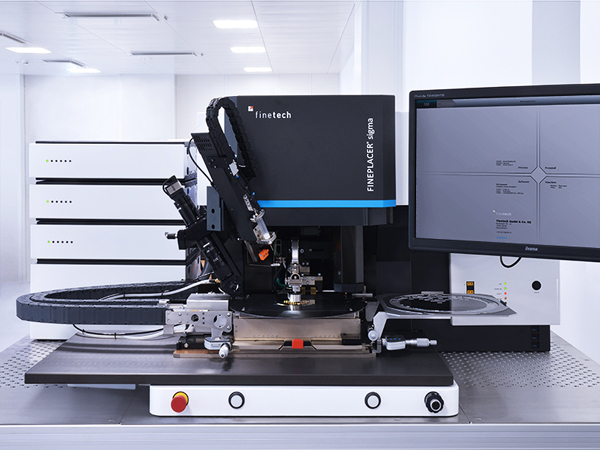

FINEPLACER® sigma

Semi-automated Sub-Micron Bonder

The FINEPLACER® sigma combines sub-micron placement accuracy with a 450 x 150 mm working area and bonding forces up to 1000 N. The system is ideal for all types of precision die bonding and flip chip applications at chip and wafer level. This includes complex 2.5D and 3D IC packages, Focal Plane Arrays (i.e. image sensors), MEMS/MOEMS, and more.

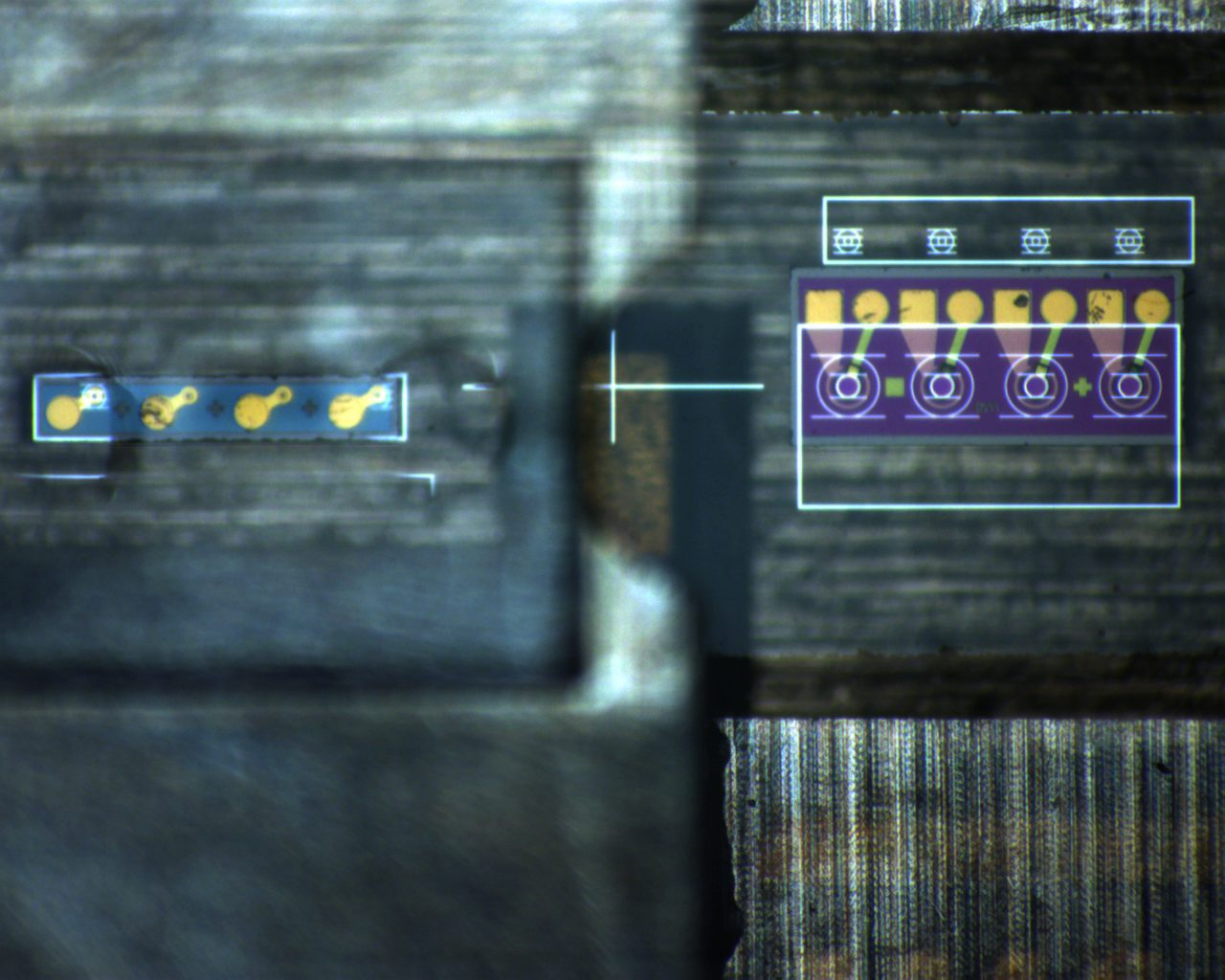

Placing small devices on large substrates is made possible by the FPXvisionTM optical system design. With this alignment system, the smallest structures at the highest magnification can be viewed across the entire field of view. Moreover, FPXvisionTM introduces pattern recognition to a die bonder with manual alignment.

The FINEPLACER® sigma embraces all features of an assembly and development platform capable of handling an unlimited spectrum of applications and prepared for future technologies.

Highlights*

- Sub micron placement accuracy

- Supports 300 mm wafers

- Bonding forces up to 1000 N

- FPXvisionTM - high resolution for all magnifications

- Software guided alignment verification

- Touch screen GUI

- Modular design for flexible configurations

Technologies

- Thermocompression bonding

- Thermo- / ultrasonic bonding

- Soldering (AuSn / eutectic, Indium, C4)

- Adhesive technologies

- ACF/ ACP bonding

- UV / thermal curing

- Cu / Cu bonding, copper pillar bonding

- Precision vacuum die bonding

- Sintering

- Micro mechanical assembly

Applications

- Wafer level packaging (FOWLP, W2W, C2W)

- 2.5D and 3D IC packaging (TSV)

- Multi chip packaging (MCM, MCP)

- Flip chip bonding (face down)

- Precision die bonding (face up)

- µLED and µLED array bonding

- Optical package assembly

- MEMS/MOEMS packaging

- Sensor assembly

- Glass-on-glass, chip-on-glass, chip-on-flex

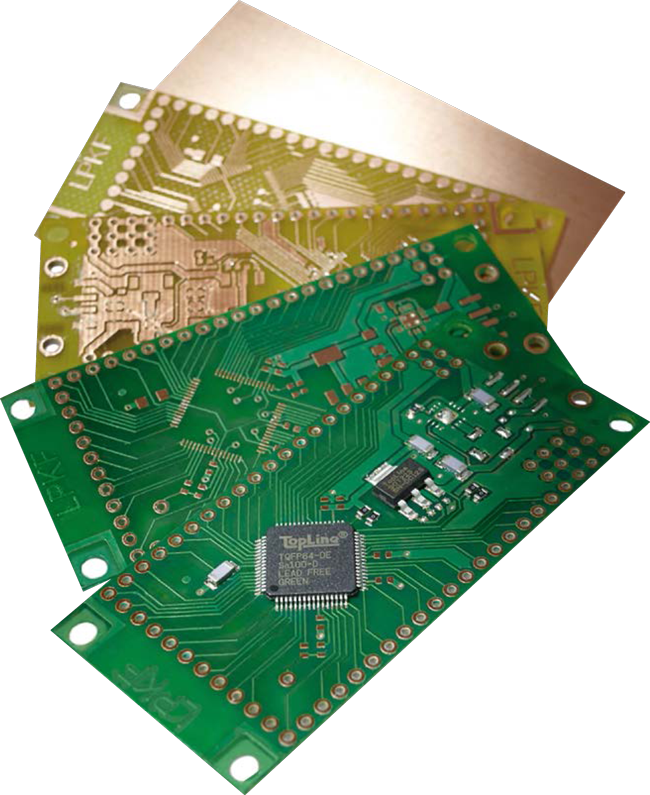

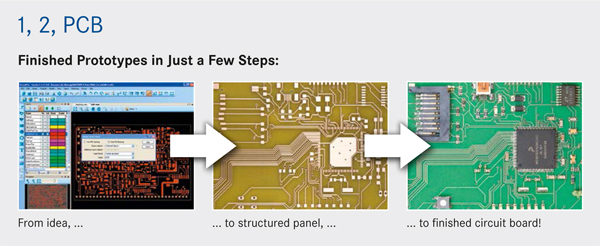

Get PCB Prototypes Sooner with In-House Rapid PCB Prototyping

Get PCB Prototypes Sooner with In-House Rapid PCB Prototyping

Siglent’s SSA3000X family of spectrum analyzers offer a frequency range of 9 KHz to 2.1 GHz / 3.2 GHz. With their light weight, small size, and friendly user interface, the SSA3000s present a bright easy to read display, powerful and reliable automatic measurements, and plenty of impressive features. Applications are many, but include research and development, education, production, maintenance, and many more.

Siglent’s SSA3000X family of spectrum analyzers offer a frequency range of 9 KHz to 2.1 GHz / 3.2 GHz. With their light weight, small size, and friendly user interface, the SSA3000s present a bright easy to read display, powerful and reliable automatic measurements, and plenty of impressive features. Applications are many, but include research and development, education, production, maintenance, and many more. Bring your best to work.

Bring your best to work. See it. Save it. Share it.

See it. Save it. Share it. SMD Rework System

SMD Rework System SIGLENT’s SDS2000X Series Super Phosphor Oscilloscopes are available in bandwidths of 70 MHz, 100 MHz, 200 MHz and 300 MHz, maximum sample rate of 2 GSa/s, and come with a maximum record length of 140 Mpts. The most commonly used functions can be accessed with its user-friendly one-button design.

SIGLENT’s SDS2000X Series Super Phosphor Oscilloscopes are available in bandwidths of 70 MHz, 100 MHz, 200 MHz and 300 MHz, maximum sample rate of 2 GSa/s, and come with a maximum record length of 140 Mpts. The most commonly used functions can be accessed with its user-friendly one-button design. Real-time sampling rate up to 2 GSa/s

Real-time sampling rate up to 2 GSa/s

In 1886, our iconic brand was born. So much has changed since we made our first saws. Our commitment to making the world's finest tools is one thing that hasn't.To celebrate this with you we developed a tool trolley filled with our innovative products.

In 1886, our iconic brand was born. So much has changed since we made our first saws. Our commitment to making the world's finest tools is one thing that hasn't.To celebrate this with you we developed a tool trolley filled with our innovative products. Technolab Video microscopy with sharpness never seen before

Technolab Video microscopy with sharpness never seen before

New Tektronix TBS2000 Oscilloscope.

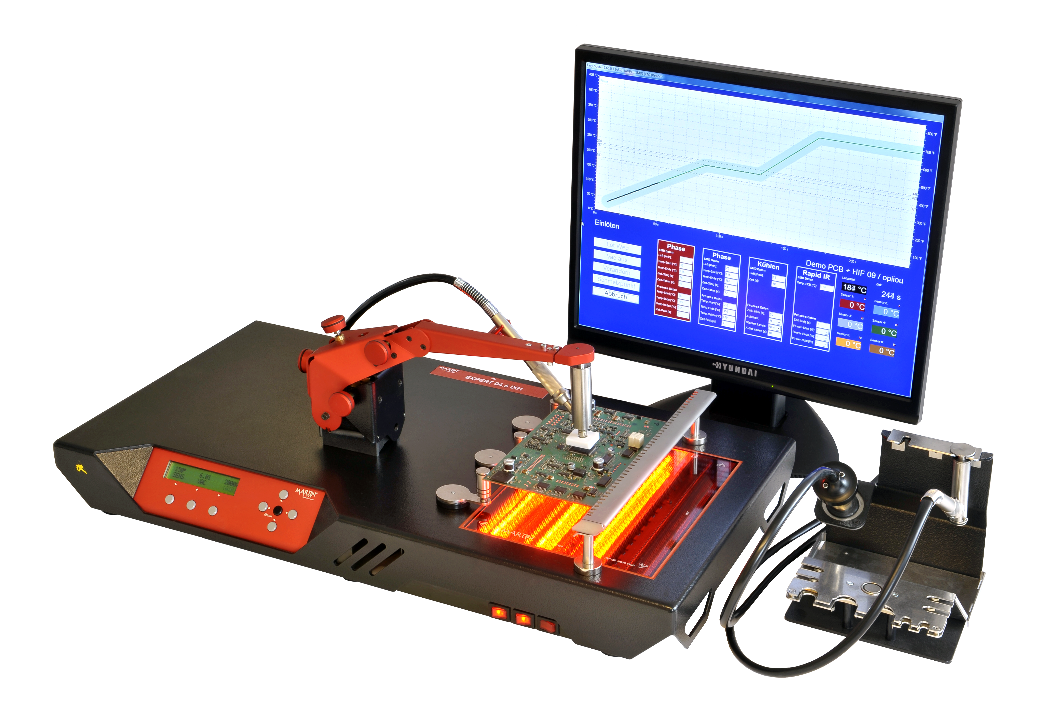

New Tektronix TBS2000 Oscilloscope. Manual rework of BGA, QFP and Sockets

Manual rework of BGA, QFP and Sockets